Cairan Pembersih Untuk Strip Baja

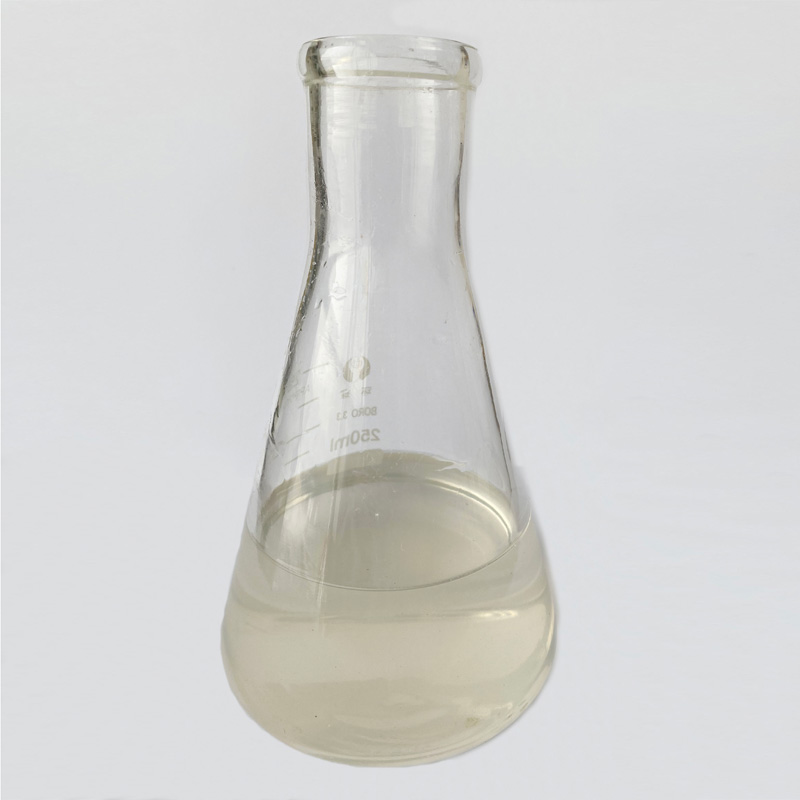

pembersih untuk baja strip adalah zat cair pembersih lemak alkali. . Sangat cocok untuk kimia degreasing elektroplating atau electroless plating. itu juga dapat digunakan untuk pembersih baja listrik.

sebagai pembersih baja strip, Ini memiliki efek pembersihan yang baik pada semua jenis minyak organik, minyak mineral, minyak bergulir dan kotoran.

Produk ini memiliki keunggulan degreasing yang cepat, pengoperasian yang sederhana, dan manajemen yang nyaman. Metode perawatan dapat berupa penyemprotan, pencelupan dan metode lainnya.

Degreaser bt-4336 is an alkaline degreaser made from a variety of alkali, surfactants, and water treatment agents. Compared with liquid degreaser, powder degreaser has one more electrolytic degreaser.

Two, groove matching method:

· Chemical and electrolytic degreasing:

4. Fill the treatment tank with 80% water.

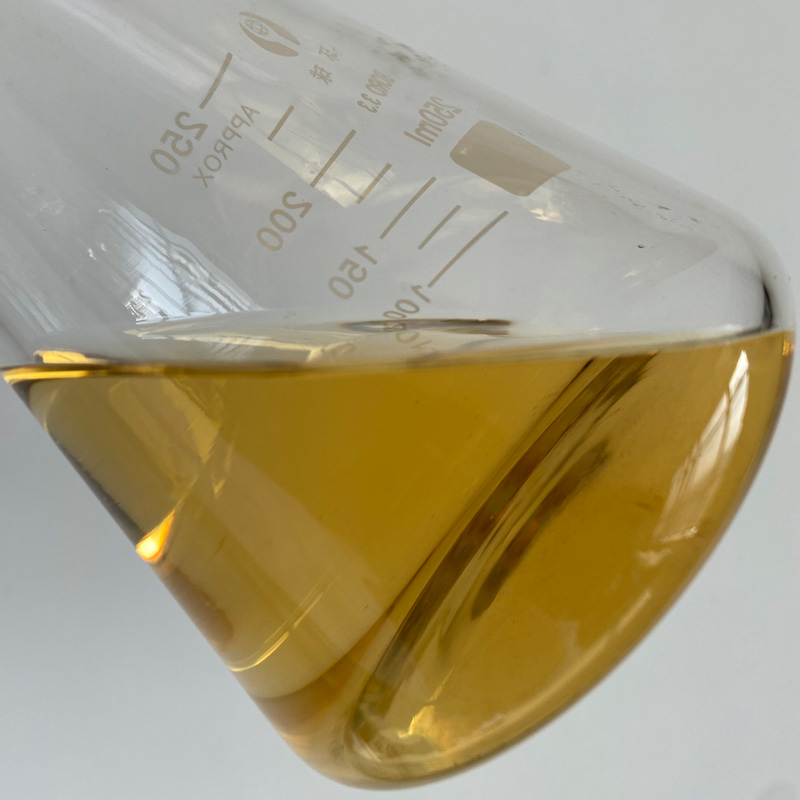

5. Add degreaser bt-4336 into the treatment tank, at the rate of 2%, and add appropriate amount of defoamer according to the production situation

6. Add water to the working liquid level, stir thoroughly, and heat to the required temperature of the process. The temperature should be between 35-75℃, otherwise the degreaser will volatilize and freeze due to too high or too low temperature.

Bt-4336 free alkalinity :12-16 Pt.

Powder degreaser and liquid degreaser in the use of differences: powder degreaser in order to play the effect of degreaser, need to be dissolved in water before adding to the degreaser tank, and liquid degreaser does not need to dissolve in advance, directly added to the degreaser tank; Liquid degreaser is suitable for automatic dosing device, while powder degreaser needs to be dissolved in advance to achieve automatic dosing.

Soaking degreasing and spray degreasing are different in use: soaking degreasing time can be long or short, and spray degreasing time is fixed, generally can not be changed; Relatively speaking, soaking degreasing because there is no external force, so the requirements are higher. In addition, spray degreasing should not have too much foam, requiring the surfactant to be low foam. Powder degreaser and liquid degreaser can be used in soaking and spraying processes. In terms of results, liquid degreaser is generally better.